Unveiling Excellence: The Dynamics of Die Casting Mold Manufacturing in China

I. Introduction

In the intricate world of manufacturing, die casting molds play a pivotal role in ensuring precision, efficiency, and quality. This article delves into the heart of die casting mold production, with a specific focus on China’s burgeoning industry. Let’s explore the nuances of die casting molds, their types, materials, design considerations, and the cutting-edge technology propelling the sector forward.

II. Types of Die Casting Molds

Cold Chamber Die Casting Mold

Cold chamber die casting molds are integral to numerous manufacturing processes, offering distinct advantages and disadvantages. The cold chamber die casting process involves injecting molten metal into a mold at a controlled temperature. This method is particularly suitable for metals with high melting points, providing enhanced durability and strength to the final product. Despite its efficacy, it comes with certain drawbacks such as longer cycle times and higher production costs.

Hot Chamber Die Casting Mold

Contrastingly, hot chamber die casting molds simplify the process by melting the metal within the casting machine itself. This reduces cycle times, making it ideal for mass production. However, it’s more suitable for metals with lower melting points like zinc and magnesium. The hot chamber die casting process is not without its limitations, particularly in terms of the materials it can handle.

III. Die Casting Materials

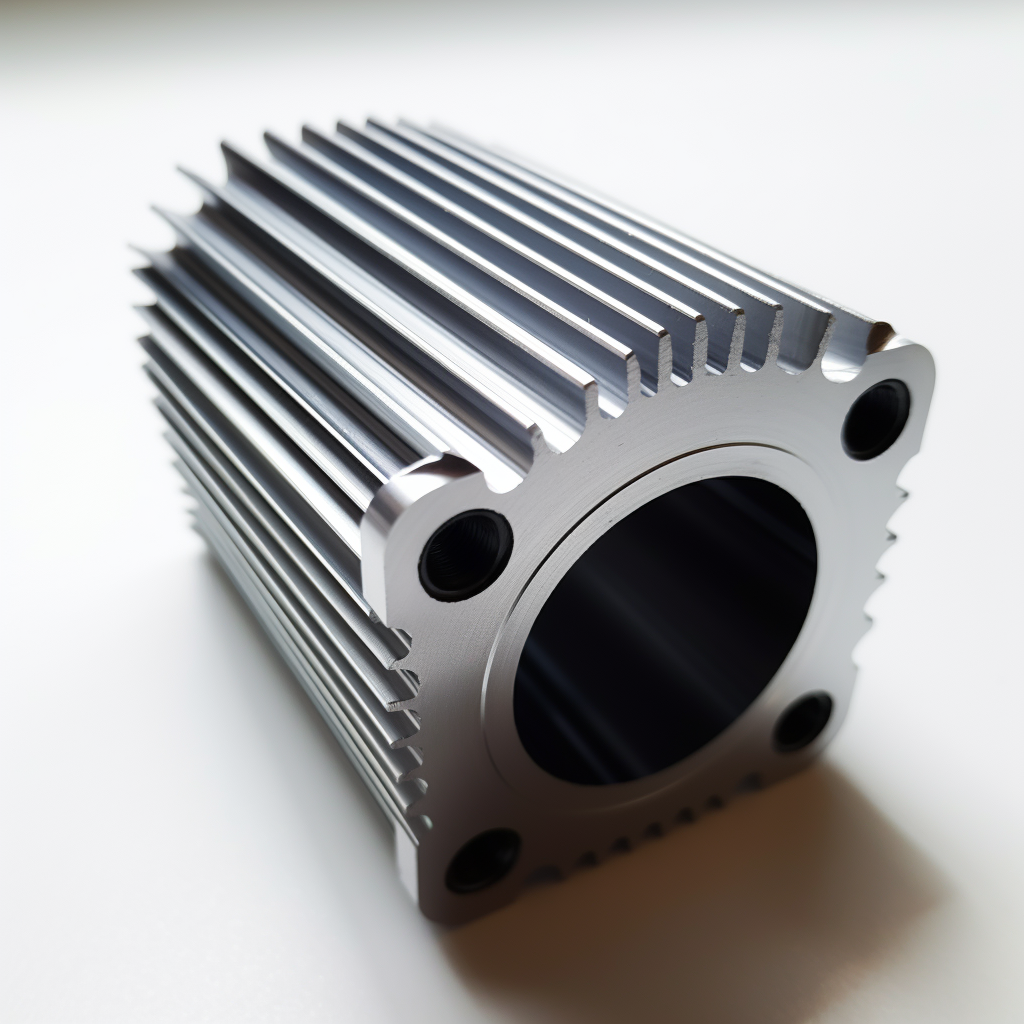

The choice of materials in die casting molds is critical for ensuring the desired properties in the final product. Aluminum, known for its lightweight and corrosion-resistant attributes, is a popular choice. Zinc and magnesium, on the other hand, offer specific advantages in terms of malleability and thermal conductivity. The selection criteria for die casting materials depend on factors like the intended application, desired characteristics of the final product, and cost considerations.

IV. Die Casting Mold Design

The success of die casting hinges on meticulous design considerations. Part geometry, material flow, cooling systems, and ejection mechanisms are critical components of an effective die casting mold design. Precision is paramount, as even minor deviations can lead to defects in the final product. With advancements in computer-aided design (CAD) technologies, die casting mold designers in China are pushing the boundaries of innovation.

V. Die Casting Mold Manufacturing Process in China

China has emerged as a global powerhouse in die casting mold manufacturing. Boasting a robust industry, key players in China’s market adhere to stringent quality control measures and standards. The manufacturing process involves a comprehensive approach, from design validation to prototype development and final production. The industry’s growth is underscored by a commitment to technological advancements and a keen focus on meeting international standards.

VI. Advancements in Die Casting Mold Technology

In the era of Industry 4.0, die casting mold manufacturing in China is witnessing a technological revolution. Smart manufacturing, data analytics, and automation are seamlessly integrated into the production process. This not only enhances efficiency but also allows for real-time monitoring and adaptive manufacturing strategies. As the industry evolves, so does the technology driving it forward.

VII. Challenges and Solutions

Despite the remarkable progress, die casting mold manufacturers in China face challenges ranging from complex design requirements to regulatory compliance issues. Innovative solutions, such as the adoption of advanced simulation tools for design validation and stringent quality control protocols, are being implemented to overcome these hurdles. The industry’s resilience lies in its ability to adapt and find inventive solutions to emerging challenges.

VIII. Case Studies

Examining successful die casting mold projects in China provides valuable insights into the industry’s capabilities. From automotive components to consumer electronics, these case studies showcase the versatility and reliability of Chinese die casting mold manufacturers. Lessons learned from notable projects contribute to the continuous refinement of manufacturing processes and methodologies.

IX. Future Trends in Die Casting Mold Industry

Looking ahead, the die casting mold industry in China is poised for continued growth. Technological advancements, including the integration of artificial intelligence and sustainable manufacturing practices, will define the sector’s trajectory. As global demand for high-quality precision components rises, China’s die casting mold industry stands at the forefront of innovation.

X. Conclusion

In conclusion, the die casting mold industry in China encapsulates a journey marked by precision, innovation, and a commitment to excellence. From the intricacies of mold design to the implementation of cutting-edge technologies, China’s manufacturers continue to shape the landscape of global manufacturing. As the industry evolves, it not only meets current demands but also anticipates future needs, solidifying its position as a leader in die casting mold production.

Are you in need of high-quality aluminum die casting services? Look no further than CNM Tech China die casting manufacturer! Our team of experts specializes in aluminum, zinc, and magnesium die casting, as well as machining parts, metal stamping, and plastic molds making.

With over 18 years of experience, you can trust that our die casting products are exemplary and cost-effective. We employ advanced equipment and machinery to ensure the highest quality solutions.

We have been made many type of aluminum die casting, zinc die casting, magnesium die casting from flow meter housing and valves to lighting fixture parts, automobile parts, and decorative hardware, we manufacture a wide range of products to meet your needs. And, as an added bonus, we also export various aluminum casting, zinc die casting, and magnesium casting products, as well as machining parts and injection molded parts.

Don’t settle for subpar aluminum casting services. Choose CNM Tech die casting China manufacturer for exceptional quality and affordable prices. Contact us today to learn more about our services and how we can help meet your die casting needs!