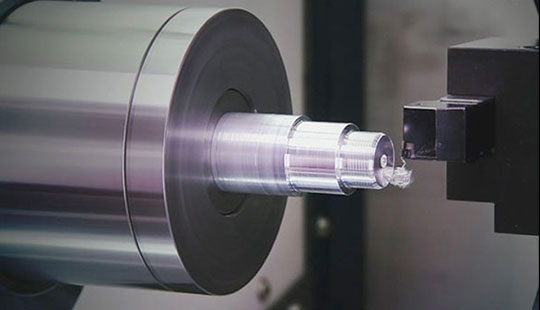

Turning of Aluminum Parts: Precision CNC Machining for High-Quality Components

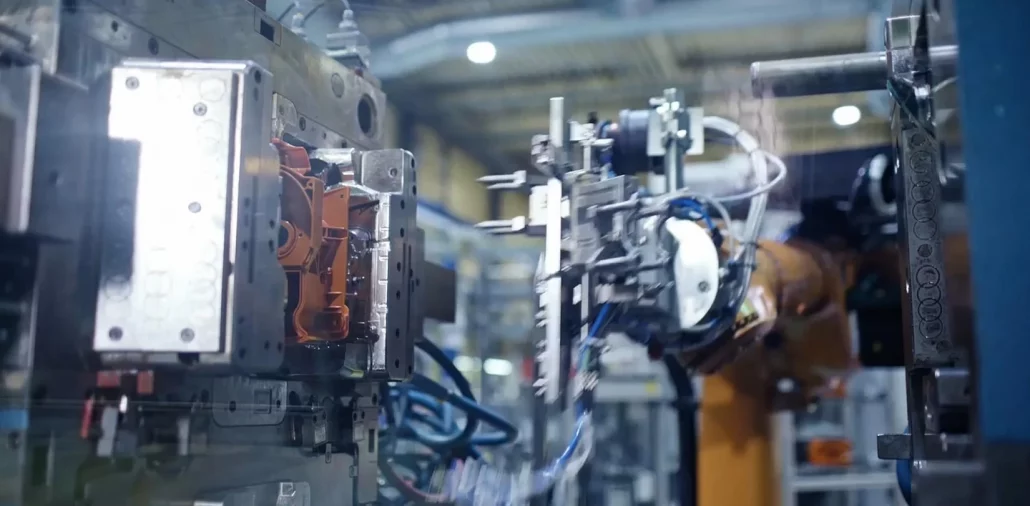

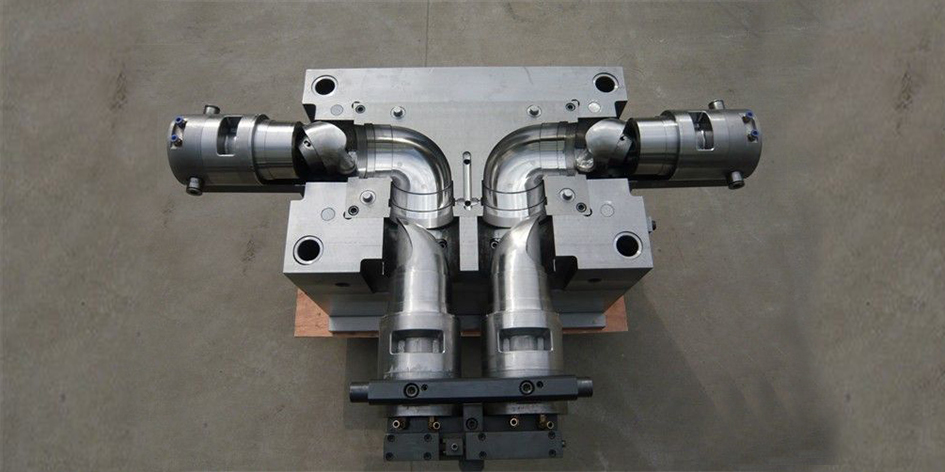

Aluminum is one of the most widely used metals in manufacturing due to its lightweight, excellent machinability, and corrosion resistance. The turning of aluminum parts plays a crucial role in producing high-precision components for industries such as aerospace, automotive, electronics, and medical devices. With the advancement of CNC machining technology, precision turning of aluminum parts […]

Turning of Aluminum Parts: Precision CNC Machining for High-Quality Components Read More »