Aluminum and cast aluminum are both widely used metals in a variety of applications. However, they have some key differences that are important to understand. In this article, we will explore the definition of each metal, their properties, and the key differences between them. We will also look at the applications of each metal and provide a conclusion.

A. Definition of Aluminum and Cast Aluminum

Aluminum is a lightweight and versatile metal that is widely used in a variety of applications. It is the third most abundant metal in the earth’s crust and is known for its low density, malleability, and corrosion resistance. Cast aluminum is a type of aluminum that is produced by pouring molten aluminum into a mold and allowing it to solidify.

B. Importance of Understanding the Differences between the Two

Understanding the differences between aluminum and cast aluminum is important for a variety of reasons. For example, aluminum and cast aluminum have different strength and durability properties, which can impact their suitability for different applications. Additionally, the production process for each metal can impact its cost and availability. Understanding these differences can help manufacturers make informed decisions when selecting the right metal for their needs.

C. Purpose of the Article

The purpose of this article is to provide an overview of the differences between aluminum and cast aluminum, including their properties, production processes, and applications. By the end of this article, readers should have a clear understanding of the key differences between these two metals and be able to make informed decisions about which one is best suited for their needs.

II. Definition of Aluminum

A. Overview of Aluminum as a Metal

Aluminum is a silvery-white metal that is lightweight and highly versatile. It is widely used in a variety of applications due to its low density, malleability, and corrosion resistance. Aluminum is also relatively inexpensive compared to other metals, making it a popular choice for manufacturers.

B. Properties of Aluminum

Aluminum has several properties that make it ideal for a variety of applications. Some of the key properties of aluminum include:

- Low density: Aluminum has a low density compared to other metals, which makes it an ideal choice for applications where weight is a concern.

- Malleability: Aluminum is highly malleable, which means it can be easily shaped and molded into a variety of forms.

- Corrosion resistance: Aluminum is highly resistant to corrosion, which makes it a popular choice for applications in harsh environments.

- Low melting point: Aluminum has a low melting point of 660 degrees Fahrenheit, which makes it easier to work with than other metals.

- Good thermal conductivity: Aluminum has good thermal conductivity, which makes it a popular choice for applications in heating and cooling.

C. Uses of Aluminum

Aluminum is used in a wide variety of applications, including:

- Building and construction: Aluminum is used in building materials such as windows, doors, and roofing due to its strength, durability, and corrosion resistance.

- Automotive: Aluminum is used in the automotive industry for vehicle bodies, wheels, and engine components due to its lightweight properties and corrosion resistance.

- Electronics: Aluminum is used in the electronics industry for components such as circuit boards and connectors due to its good thermal conductivity and electrical conductivity.

- Packaging: Aluminum is used in packaging due to its lightweight properties and resistance to corrosion.

- Aerospace: Aluminum is used in the aerospace industry for aircraft components due to its strength, durability, and corrosion resistance.

III. Definition of Cast Aluminum

A. Overview of Cast Aluminum as a Metal

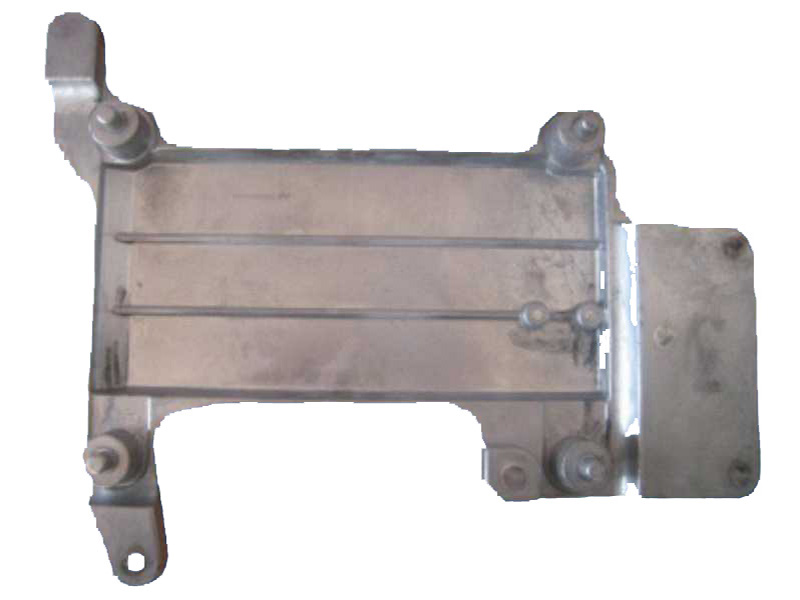

Cast aluminum is a type of aluminum that is produced by pouring molten aluminum into a mold and allowing it to solidify. Cast aluminum is typically used in applications where a high level of accuracy and consistency is required, such as in the production of engine blocks and other automotive components.

B. Properties of Cast Aluminum

Cast aluminum has several properties that make it ideal for a variety of applications. Some of the key properties of cast aluminum include:

- High strength: Cast aluminum can be produced with high levels of strength, which makes it ideal for applications where durability is a concern.

- Good thermal conductivity: Cast aluminum has good thermal conductivity, which makes it a popular choice for applications in heating and cooling.

- Good corrosion resistance: Cast aluminum is highly resistant to corrosion, which makes it a popular choice for applications in harsh environments.

- Good formability: Cast aluminum can be easily shaped and molded into a variety of forms, which makes it a popular choice for applications where a high level of precision is required.

C. Uses of Cast Aluminum

Cast aluminum is used in a wide variety of applications, including:

- Automotive: Cast aluminum is used in the automotive industry for engine components, transmission cases, and other applications due to its strength, durability, and corrosion resistance.

- Construction: Cast aluminum is used in construction for applications such as window frames and door panels due to its high strength and corrosion resistance.

- Electrical: Cast aluminum is used in the electrical industry for components such as transformers and switchgear due to its good thermal conductivity and electrical conductivity.

- Aerospace: Cast aluminum is used in the aerospace industry for applications such as airframe components and engine parts due to its high strength and corrosion resistance.

IV. Key Differences between Aluminum and Cast Aluminum

A. Production process

The production process for aluminum and cast aluminum is different. Aluminum is produced by melting aluminum ore and other raw materials and then casting it into various shapes. Cast aluminum is produced by pouring molten aluminum into a mold and allowing it to solidify.

B. Strength and durability

Aluminum and cast aluminum have different strength and durability properties. Cast aluminum is generally stronger and more durable than aluminum due to its high strength and corrosion resistance.

C. Appearance and finish

Aluminum and cast aluminum have different appearance and finish properties. Aluminum can be finished in a variety of ways, including anodizing, painting, and powder coating. Cast aluminum can also be finished in a variety of ways, but it may have a slightly different appearance due to the manufacturing process.

D. Cost and availability

Aluminum and cast aluminum have different cost and availability properties. Aluminum is generally less expensive than cast aluminum due to its widespread availability and lower production costs.

E. Environmental impact

Aluminum and cast aluminum have different environmental impact properties. Cast aluminum production can have a higher environmental impact due to the energy required to melt and cast the metal.

V. Applications of Aluminum and Cast Aluminum

A. Aluminum

Aluminum is used in a wide variety of applications due to its lightweight and corrosion-resistant properties. Some of the key applications of aluminum include:

- Building and construction: Aluminum is used in the construction industry for applications such as windows, doors, and roofing due to its strength, durability, and corrosion resistance.

- Automotive: Aluminum is used in the automotive industry for vehicle bodies, wheels, and engine components due to its lightweight properties and corrosion resistance.

- Electronics: Aluminum is used in the electronics industry for components such as circuit boards and connectors due to its good thermal conductivity and electrical conductivity.

- Packaging: Aluminum is used in the packaging industry for applications such as cans and foil due to its lightweight properties and resistance to corrosion.

- Aerospace: Aluminum is used in the aerospace industry for aircraft components due to its strength, durability, and corrosion resistance.

B. Cast Aluminum

Cast aluminum is used in a wide variety of applications due to its high strength and corrosion-resistant properties. Some of the key applications of cast aluminum include:

- Automotive: Cast aluminum is used in the automotive industry for engine components, transmission cases, and other high-strength applications due to its high strength and corrosion resistance.

- Construction: Cast aluminum is used in construction for applications such as window frames and door panels due to its high strength and corrosion resistance.

- Electrical: Cast aluminum is used in the electrical industry for components such as transformers and switchgear due to its good thermal conductivity and electrical conductivity.

- Aerospace: Cast aluminum is used in the aerospace industry for high-strength applications such as airframe components and engine parts due to its high strength and corrosion resistance.

VI. Conclusion

In conclusion, aluminum and cast aluminum are both popular materials used in a wide variety of applications due to their unique properties. While they are similar in many ways, there are also some key differences between the two materials, including their production process, strength and durability, appearance and finish, cost and availability, and environmental impact. By understanding the properties and applications of aluminum and cast aluminum, manufacturers and consumers can make informed decisions about which material is best suited for their specific needs.

Looking for a reliable and efficient China die casting manufacturer? Look no further than GC Precision Mold Co. Ltd! Formerly known as Aluminum Die Casting (China) Ltd., we specialize in die casting parts and have two manufacturing companies for high pressure die casting (aluminum die casting, zinc die casting, magnesium die casting), aluminum gravity casting, aluminum sand casting, aluminum profile, aluminum precision machining, metal die casting, and forging casting.

Our head office is located in Dong Guan City, Guang Dong Province, and our resident senior Western management team permanently monitors the development of products, projects, manufacturing processes, quality assurance, and control.

We take pride in carrying out assembly operations in our own plant to ensure the quality of complex, engineered, and critical-to-manufacture products. We also protect the intellectual property of our customers.

Choose GC Precision Mold die casting manufacturer for exceptional quality and service. Contact us today to learn more about our services and how we can help meet your die casting needs!