Indiana has become a key player in the U.S. manufacturing industry, particularly in injection molding. With a strong industrial base, skilled workforce, and proximity to major markets, the state is home to numerous Indiana injection molding companies that serve a wide range of industries, including automotive, medical, consumer products, and aerospace. These companies specialize in producing high-quality plastic parts using advanced technologies and efficient production methods. In this article, we will explore the benefits of injection molding in Indiana, key companies in the state, the industries they serve, and what makes Indiana an ideal location for plastic manufacturing.

Why Indiana is a Leader in Injection Molding

Indiana has a long history of manufacturing excellence, with a business-friendly environment that encourages industrial growth. One of the biggest advantages of injection molding companies in Indiana is their access to a skilled workforce. The state has several technical schools and universities that offer specialized training in plastics engineering and manufacturing processes. This ensures that companies have a steady supply of qualified workers who understand the complexities of injection molding.

Another advantage is Indiana’s central location in the United States. The state is strategically positioned near major automotive and industrial hubs, making it easy for manufacturers to ship products to customers quickly and efficiently. Many injection molding companies in Indiana benefit from this logistical advantage, allowing them to serve clients across the country with lower transportation costs.

Indiana also offers a business-friendly regulatory environment and lower operational costs compared to other industrial states. Companies that set up manufacturing facilities in Indiana can benefit from tax incentives, affordable energy costs, and a strong infrastructure that supports large-scale industrial operations. These factors contribute to the state’s reputation as a top destination for injection molding.

Key Injection Molding Companies in Indiana

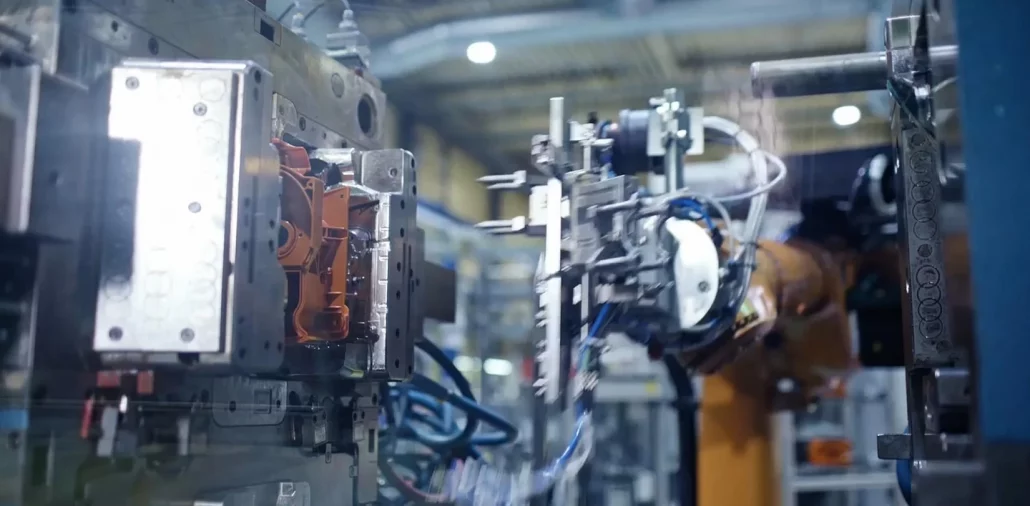

Indiana is home to many established injection molding companies that provide a wide range of services. Some specialize in high-volume production, while others focus on custom molding solutions for niche industries. These companies use advanced technology, including robotics and automation, to enhance production efficiency and ensure high-quality output.

Many Indiana injection molding companies offer comprehensive services, from design and prototyping to full-scale production and assembly. This makes them valuable partners for businesses looking to develop new plastic products or improve existing manufacturing processes. The presence of these companies in Indiana has made the state a major hub for plastic component production, supplying parts to industries across the United States.

Industries Served by Indiana Injection Molding Companies

Injection molding companies in Indiana serve a wide range of industries, with each sector having unique requirements for plastic components. One of the largest industries that rely on injection molding is the automotive sector. Many Indiana manufacturers produce precision-molded plastic parts for vehicles, including interior and exterior components, under-the-hood parts, and structural reinforcements. Given Indiana’s strong automotive industry, local injection molders play a crucial role in supporting major car manufacturers.

The medical industry also relies heavily on Indiana injection molding companies to produce high-quality plastic components used in medical devices, surgical instruments, and laboratory equipment. These products require strict quality control and compliance with FDA regulations, which many Indiana manufacturers are equipped to handle.

Consumer goods manufacturers also benefit from Indiana’s injection molding capabilities. From household appliances to packaging solutions, plastic injection molding is used to create durable and cost-effective products that meet consumer demands. Many companies in Indiana specialize in producing plastic enclosures, containers, and packaging for food and beverage applications.

Aerospace and electronics industries also turn to Indiana injection molding companies for precision-molded plastic parts. These industries require lightweight, high-performance materials that can withstand extreme conditions, and Indiana manufacturers have the expertise to meet these stringent demands.

Advanced Technologies Used by Indiana Injection Molding Companies

The injection molding industry has evolved significantly in recent years, and companies in Indiana are embracing advanced technologies to stay competitive. Many manufacturers are incorporating automation and robotics into their production lines, which helps improve efficiency, reduce costs, and maintain consistency in part quality.

Another key advancement is the use of computer-aided design (CAD) and simulation software in the mold design process. These tools allow engineers to optimize mold designs before production begins, reducing the risk of defects and minimizing material waste. By using state-of-the-art technology, Indiana injection molding companies can produce high-quality components with greater precision and efficiency.

The use of sustainable materials and environmentally friendly manufacturing practices is also becoming more common in Indiana. Many companies are investing in biodegradable plastics and recycled materials to reduce their environmental impact. This shift toward sustainability benefits both manufacturers and their customers, as it aligns with growing consumer and regulatory demands for eco-friendly products.

Benefits of Working with Indiana Injection Molding Companies

Businesses that choose to work with injection molding companies in Indiana gain several advantages. First and foremost, Indiana’s injection molders are known for their commitment to quality. Many companies adhere to strict industry standards and certifications, ensuring that the plastic parts they produce meet high-performance requirements.

Another benefit is cost-effectiveness. Due to Indiana’s lower operational costs, companies can offer competitive pricing for their services. This makes Indiana an attractive location for businesses looking to reduce manufacturing expenses without compromising on quality.

Quick turnaround times are another reason why many businesses prefer working with Indiana injection molding companies. Thanks to the state’s central location and efficient logistics network, manufacturers can deliver products faster to customers across the country. This is especially beneficial for industries that require rapid production cycles, such as automotive and medical device manufacturing.

Additionally, Indiana’s strong network of suppliers and support industries enhances the capabilities of local injection molding companies. Many mold makers, material suppliers, and engineering firms operate in the state, allowing for seamless collaboration throughout the manufacturing process. This ecosystem helps companies streamline their operations and maintain high levels of efficiency.

Challenges Faced by Injection Molding Companies in Indiana

Despite the many advantages of manufacturing in Indiana, injection molding companies do face some challenges. One of the biggest challenges is workforce availability. While Indiana has a strong industrial workforce, there is still a growing demand for skilled workers in injection molding and related fields. Companies must invest in training and workforce development programs to ensure they have the necessary talent to support their operations.

Another challenge is competition from overseas manufacturers. Many businesses look to offshore suppliers for cheaper injection molding services, particularly in regions where labor costs are lower. However, Indiana manufacturers are addressing this challenge by emphasizing quality, reliability, and shorter lead times, which are often more valuable than lower costs alone.

The rising cost of raw materials is another factor that impacts injection molding companies in Indiana. Prices for plastics and resins fluctuate due to market conditions, affecting overall production costs. To mitigate this challenge, many manufacturers are exploring alternative materials and improving efficiency in their production processes to minimize waste.

The Future of Injection Molding in Indiana

The future of Indiana’s injection molding industry looks promising, with continued growth expected across multiple sectors. Advances in technology, including automation, 3D printing, and sustainable materials, will further enhance the capabilities of local manufacturers. As businesses increasingly prioritize domestic production to avoid supply chain disruptions, Indiana’s injection molding industry is well-positioned to expand. Indiana injection molding companies are also expected to play a larger role in emerging industries such as electric vehicles and renewable energy. These industries require innovative plastic solutions, and Indiana’s strong manufacturing infrastructure makes it an ideal location for research and development in advanced plastics manufacturing.

Indiana has established itself as a leading hub for injection molding, offering numerous advantages for businesses looking for high-quality plastic manufacturing solutions. The state’s skilled workforce, central location, advanced technologies, and cost-effective operations make it an attractive destination for companies in various industries. Despite challenges such as competition and rising material costs, Indiana injection molding companies continue to thrive by focusing on innovation, efficiency, and customer satisfaction. As the industry evolves, Indiana will remain a key player in the U.S. injection molding market, providing essential plastic components for industries nationwide.

Indiana Injection Molding Companies: A Thriving Industry

Indiana has long been recognized as a manufacturing powerhouse, with injection molding playing a significant role in its industrial landscape. The state’s strategic location, skilled workforce, and robust supply chain infrastructure make it an attractive destination for companies looking to produce high-quality plastic components. As demand for precision-molded plastic parts continues to grow across various industries, Indiana injection molding companies are investing in advanced technologies, sustainable practices, and efficient production processes to stay competitive.

In this extended discussion, we will explore additional aspects of the injection molding industry in Indiana, including the role of automation, sustainability efforts, customization capabilities, and future trends shaping the sector. We will also delve deeper into the various industries benefiting from injection molding and how Indiana companies continue to innovate to meet evolving market needs.

The Role of Automation in Injection Molding

Automation has revolutionized the injection molding industry, significantly improving production efficiency, consistency, and cost-effectiveness. Many Indiana injection molding companies have embraced automation to streamline operations, reduce human error, and enhance overall productivity.

One of the key applications of automation in injection molding is the use of robotic systems. These robots handle tasks such as part removal, quality inspection, and assembly, allowing manufacturers to produce plastic components with greater precision and speed. Automated systems also contribute to reduced labor costs, as fewer manual interventions are required throughout the production process.

In addition to robotics, smart manufacturing technologies, such as Internet of Things (IoT) sensors and artificial intelligence, are being integrated into injection molding facilities in Indiana. These technologies enable real-time monitoring of equipment performance, predictive maintenance, and data-driven decision-making. By leveraging these advancements, injection molding companies in Indiana can optimize their processes, minimize downtime, and enhance product quality.

Sustainability Efforts in Indiana Injection Molding

Sustainability has become a major focus in the injection molding industry, as businesses and consumers demand more environmentally friendly manufacturing practices. Indiana injection molding companies are taking proactive steps to reduce their environmental impact by adopting sustainable materials, minimizing waste, and improving energy efficiency.

One of the primary sustainability efforts involves the use of biodegradable and recycled plastics. Many manufacturers are incorporating post-consumer recycled resins into their production processes, reducing the reliance on virgin plastic materials. This approach not only helps divert plastic waste from landfills but also lowers production costs.

Energy efficiency is another critical aspect of sustainability in injection molding. Advanced molding machines equipped with energy-saving features, such as servo-driven hydraulic systems, consume less power while maintaining high-performance levels. Additionally, companies are investing in renewable energy sources and optimizing production schedules to reduce overall energy consumption.

Waste reduction initiatives, including closed-loop recycling systems, further enhance the sustainability of Indiana’s injection molding industry. By reprocessing scrap materials and defective parts, manufacturers can minimize material waste and contribute to a more circular economy.

Customization and Specialization in Injection Molding

Indiana injection molding companies offer a wide range of customization options to meet the unique needs of different industries. Whether it’s complex geometries, multi-material molding, or overmolding techniques, manufacturers in the state have the expertise and equipment to produce highly specialized plastic components.

Overmolding, for example, is a process where multiple materials are combined to create a single molded part. This technique is commonly used in automotive, medical, and consumer product applications to enhance product functionality, durability, and aesthetics. By integrating overmolding capabilities, Indiana injection molding companies can provide value-added solutions that cater to specific customer requirements.

Insert molding is another specialized process widely used in Indiana. This technique involves embedding metal or other materials within plastic during the molding process, creating stronger and more durable parts. It is particularly beneficial for applications requiring threaded inserts, electrical connectors, and mechanical fasteners.

The ability to customize injection-molded products extends to color matching, surface finishes, and branding elements. Many Indiana injection molding companies utilize advanced colorant systems and texture-enhancing techniques to achieve precise visual and tactile characteristics for their products.

How Different Industries Benefit from Indiana Injection Molding

Injection molding companies in Indiana serve a broad range of industries, each with specific requirements for plastic components. Let’s explore how key industries benefit from the expertise and capabilities of Indiana’s injection molders.

Automotive Industry

Indiana has a strong automotive manufacturing presence, making injection molding an essential part of the industry’s supply chain. Many injection-molded components in vehicles, including dashboards, bumpers, door panels, and under-the-hood parts, are produced by Indiana manufacturers. These companies must adhere to stringent quality and safety standards to ensure the reliability and performance of automotive parts.

Additionally, the shift toward electric vehicles (EVs) has increased demand for lightweight, high-strength plastic components. Indiana injection molding companies are at the forefront of developing innovative solutions that contribute to vehicle weight reduction, improved fuel efficiency, and enhanced overall performance.

Medical Industry

The medical industry relies on high-precision plastic components for various applications, including surgical instruments, diagnostic devices, and pharmaceutical packaging. Injection molding companies in Indiana manufacture critical medical products that require strict compliance with FDA regulations and ISO certifications.

Medical-grade plastics used in injection molding must meet biocompatibility and sterilization requirements. Indiana manufacturers employ advanced molding techniques, such as cleanroom injection molding, to produce high-quality medical components free from contamination.

Consumer Products

From household appliances to sporting goods, injection-molded plastics are a fundamental part of consumer products. Indiana injection molding companies produce a diverse range of everyday items, including electronic enclosures, kitchenware, and personal care product packaging.

Many consumer product manufacturers prioritize aesthetics and durability, requiring injection molders to offer high-quality surface finishes, color consistency, and material strength. The ability to mass-produce cost-effective, visually appealing plastic products makes Indiana a preferred location for consumer goods manufacturing.

Aerospace and Defense

The aerospace and defense industries demand precision-engineered plastic components that can withstand extreme temperatures, pressure, and environmental conditions. Injection molding companies in Indiana support these industries by producing specialized components for aircraft interiors, defense equipment, and communication systems.

Advanced thermoplastic materials, such as reinforced composites and high-performance polymers, are commonly used in aerospace applications. Indiana’s expertise in precision molding ensures that these materials are processed with the highest level of accuracy and consistency.

Future Trends in Indiana Injection Molding

The future of Indiana injection molding companies looks promising, with several emerging trends shaping the industry’s trajectory. These trends include increased automation, material innovations, and a growing focus on localized production.

Automation will continue to play a crucial role in enhancing production efficiency and reducing labor costs. Collaborative robots, or cobots, are expected to become more prevalent, working alongside human operators to improve productivity and safety in injection molding facilities.

Material innovations will drive new product development, with bio-based plastics and advanced composite materials gaining popularity. These materials offer enhanced performance characteristics while aligning with sustainability initiatives.

Localized production is another significant trend, as companies seek to reduce supply chain risks and minimize dependence on overseas manufacturers. Indiana’s strategic location and strong manufacturing ecosystem position it as an attractive destination for reshoring injection molding operations.

Conclusion

Indiana injection molding companies have solidified their place as key players in the U.S. manufacturing sector. With their ability to produce high-quality, customized plastic components for diverse industries, they continue to drive innovation and economic growth in the region.

As technology advances, sustainability efforts expand, and market demands evolve, Indiana’s injection molding industry is poised for continued success. Companies that embrace automation, material science advancements, and efficient production methods will remain competitive in the ever-changing manufacturing landscape.

For businesses seeking reliable and cost-effective injection molding solutions, Indiana offers an ideal combination of expertise, infrastructure, and innovation. Whether it’s producing high-precision automotive parts, medical devices, or consumer products, Indiana injection molding companies play a crucial role in shaping the future of plastic manufacturing.

With their commitment to quality, efficiency, and sustainability, these companies continue to push the boundaries of what’s possible in modern injection molding. Their ability to produce complex plastic components, including plastic mold solutions, further cements Indiana’s reputation as a top-tier manufacturing hub in the United States.